Resources

Featured Content

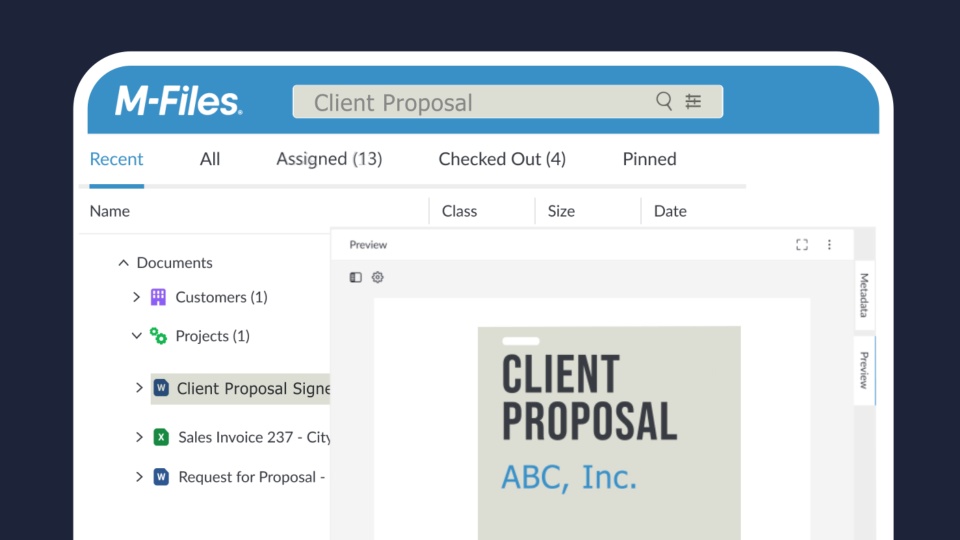

See M-Files in Action

Seeing is believing. Schedule a demo to learn more about simplified search, automatic workflows,intutive user interfaces, and built-in integrations with existing applications and file systems.

Case Studies

Case Studies

Washington University Investment Management Company

With M-Files, Washington University Investment Management Company has been able to streamline their document processing and improve oversight, consistency, and reliability in their operations.

Case Studies

FVCbank

Find out how FVCbank was able to automate their processes, achieve time savings and improve collaboration while taking care of security and compliance by implementing M-Files.

Case Studies

HUMANEXX & Hanselmann

To bring digital transformation to its document-management processes, HUMANEXX turned to Hanselmann & Compagnie, an M-Files partner, to develop a new solution for the digital management of personnel records using the M-Files knowledge work automation platform.

Case Studies

TTI, Inc. – Europe

With its success in sales processes, customs clearance, and quality management, M-Files has established itself as a central platform at TTI, Inc. - Europe.

Case Studies

Van Rhijn Bouw

Find out how Van Rhijn Bouw works with M-Files to build a solid foundation for Information Management.

Case Studies

Schera

Learn how the centralized management provided by M-Files allows Schera to easily and immediately find all accounting information, process workflows, and automate filing.

Case Studies

ello communications

With M-Files, ello communications is able to be more efficient every day and provide better value for customers.

Case Studies

St Paul’s Collegiate School

Learn how M-Files helped St Paul's Collegiate School to digitize records management and efficiently organize & access records.

Case Studies

Syntal

With M-Files, Syntal is able to quickly search for specific documents and locate any information as it is needed.

Case Studies

Indara

With M-Files, Indara achieved contract compliance, improved efficiency & customer service and reduced costs & risks.

Case Studies

Farmers Trading Company

By deploying M-Files, Farmers’ HR advisors could easily process payroll and review documents anywhere, any time.

Case Studies, Video Case Studies, Videos

Innisfree

Innisfree leveraged the power of metadata, combined with a smooth onboarding process and an easy-to-use interface to improve document management.

Case Studies

HL Technology

Learn how HL Technology created a digitalization strategy for production orders as well as automated their quality management system using M-Files.

Case Studies

Posti

By using M-Files, Posti can navigate through any future changes in business data trends, digital practices, new rules and regulations.

Case Studies

DUO Collection

Learn how digitalization using M-Files paved the way for greater transparency and efficiency for DUO Collection.

Case Studies

Charles River Laboratories

Charles River Laboratories streamlines process automation with M-Files, resulting in millions in cost savings.

Case Studies

Valeo Financial Advisors

M-Files allows Valeo to centrally manage and update document templates, so advisors spend more time on delivering their clients goals.

Case Studies

Freeze-Dry Foods

Freeze-Dry Foods unfreezes document management obstacles with M-Files.

Case Studies

Newman Women’s Shelter

Newman Women’s Shelter uses M-Files to streamline their office, freeing up staff resources to better serve the community.

Case Studies

HEB Construction

HEB Construction streamlines processes and data across diverse sites with M-Files.

Case Studies

Norco Co-operative Limited

Norco automates AP, HR, POD and Food Compliance processes and creates the opportunity for future efficiencies with M-Files.

Case Studies

Kavanagh

Kavanagh recognized that M-Files was the appropriate solution to meet its business goals.

Case Studies

Banijay

Learn how M-Files Ment allowed Banijay to create contracts faster and with greater compliance.

Case Studies

Natsure

Insurance company uses M-Files to streamline processes and saves $100K in annual salary costs.

Case Studies

vem.die arbeitgeber

Learn how M-Files document management transformed NCR&E operations by centralizing document storage resulting in anywhere accessibility of customer data.

Case Studies

Hotel Schweizerhof Bern Ag

Today, every document at Hotel Schweizerhof is stored in M-Files and all departments benefit from an enormous simplification in daily business through intelligent information management.

Case Studies

IKM Ocean Design

Thanks to M-Files, IKM management has a better overview of the business making it easier to plan for the future as well.

Case Studies

Crowe UK

Having experienced significant growth, Crowe UK required more support from its technology infrastructure with the M-Files approach.

Case Studies

Anderson Construction Ltd

New Zealand construction company achieves auditability and streamlined operations with M-Files document management system.

Case Studies

Federal Realty

Federal Realty manages dozens of top-tier properties across the country with M-Files' help.

Case Studies

Burra Foods Australia

M-Files enabled Burra Foods to halve the time it takes for its staff to manage documents, be fully compliant with its incidence management, and deliver transparent collaboration.

Case Studies

E tū Union

Discover how M-Files helped a leading union in New Zealand boost collaboration and minimize business and compliance risks.

Case Studies

Himmelwright, Huguley & Boles

Himmelwright, Huguley & Boles' clients now has instant, secure access to client tax information and can upload new content directly to M-Files.

Case Studies

Newsec

Learn how Newsec leverages M-Files EIM capabilities as a centralized solution for their asset management, CRM and ERP needs.

Case Studies

ETHRA

Find out how a non-profit organization all but eliminated paper and greatly improved efficiency in processes and compliance.

Case Studies

Wijbenga

Learn how Wijbenga B.V., a specialist in cooling tech from the Netherlands, uses M-Files document management for managing all of it's customer projects documentation.

Case Studies

Vigor Works

Vigor, an industrial services firm, leverages M-Files for quality and compliance management as well as to manage nuclear contacts and project documentation.

Case Studies

TEAM Industrial Services

Discover how TEAM turned to M-Files for help creating a new document control system which established remote access to procedures and safety documents for its technicians in the field.

Case Studies

Tampere Adult Education Center TAKK

Learn how TAKK addressed content chaos by selecting the M-Files enterprise information system.

Case Studies

Stearns Bank

To support corporate growth, Stearns Bank turned to M-Files for a centralized, easy-to-use document management system.

Case Studies

SRSI

SRSI leveraged M-Files to transition from paper to electronic document management, and as a result has reduced file processing times while also optimizing employee collaboration and automating hiring procedures.

Case Studies

Southern Hills Title

Discover how M-Files document management software helped Southern Hills Title to replace paper-based administration processes with a digital solution that allowed employees to efficiently find, manage and share confidential files internally and with approved third parties.

Case Studies

Austbrokers Countrywide

M-Files showcases its document management in a case study to show how insurance businesses can improve customer focus, streamline processes and grow.

Case Studies

SATRA Technology

In this case study discover how SATRA Technology leverages M-Files to transform and optimize business processes and quality management.

Case Studies

Roal

M-Files hybrid cloud deployment for quality management & document management helped biotech manufacturing company improve processes & customer satisfaction.

See M-Files in Action

Seeing is believing. Schedule a demo to learn more about simplified search, automatic workflows,intutive user interfaces, and built-in integrations with existing applications and file systems.

Videos & Podcasts

Case Studies, Video Case Studies, Videos

Innisfree

Innisfree leveraged the power of metadata, combined with a smooth onboarding process and an easy-to-use interface to improve document management.

See M-Files in Action

Seeing is believing. Schedule a demo to learn more about simplified search, automatic workflows, intuitive user interfaces, and built-in integrations with existing applications and file systems.